Manufacturing Processes

Kiln Fired Shades

The K Lamp is cast and kiln fired at 1075 degrees before being carefully assembled and finished by hand in our studio.

Shop K Lamps

Handspun Metal

Our Pitch Pendants are handspun from high quality aluminium. Light sanding throughout the process ensures a smooth finish. Each Pitch Pendant is quality checked one by one and evenly spray painted in one of eight colour choices.

Shop Pitch Pendants

Handblown Glass

Our Knot Lamp Shades are individually glass blown and reach temperatures above 900 degrees celcius. The glass is allowed to cool before being cut down to an appropriate size, ready for sanding. Wet and dry sanding removes any roughness and leaves a smooth even finish on both the top and the bottom. All of the glass shades are passed through quality control checks. The knots are hand tied and available in twelve colour variants.

Shop Knot Lamps

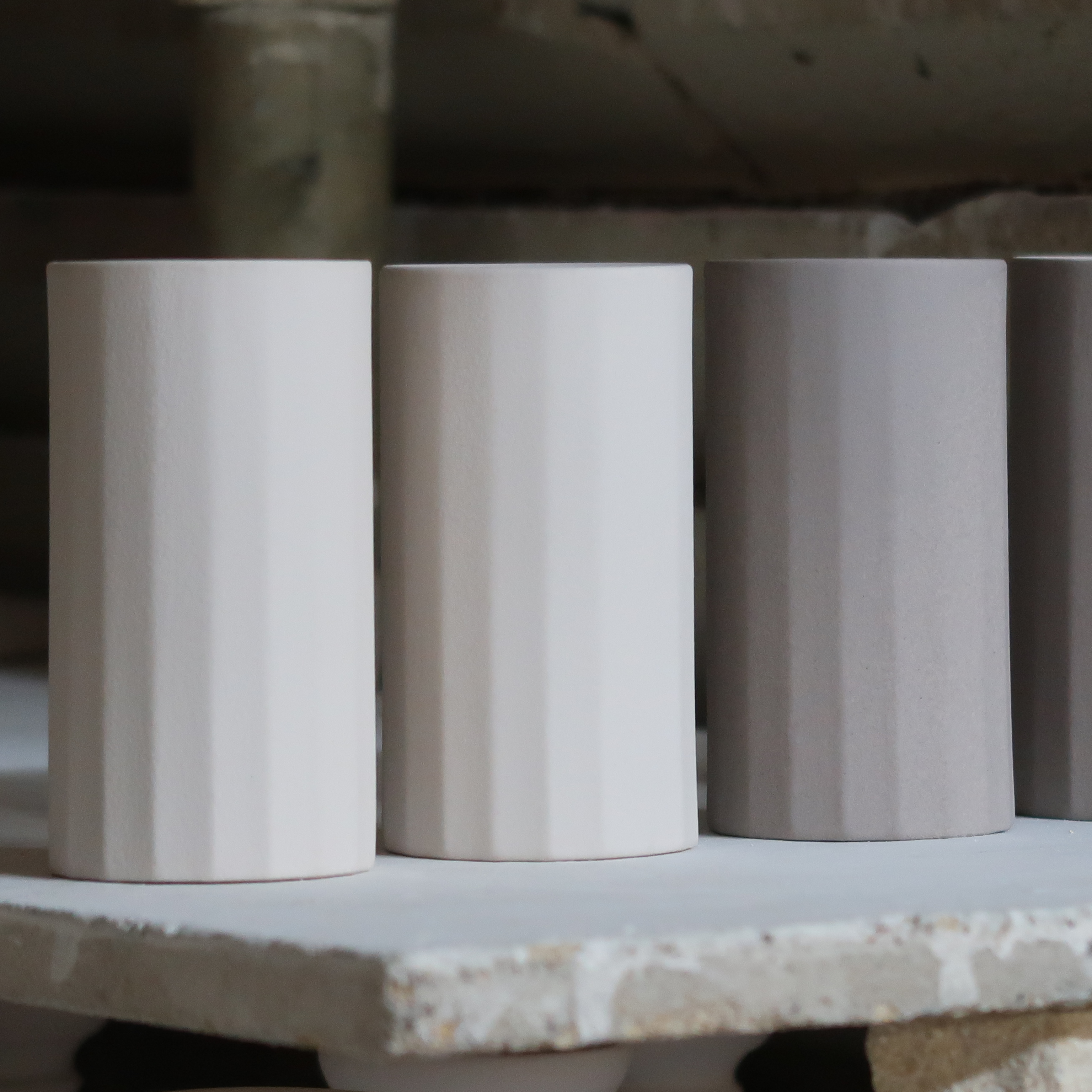

Slip Casted Ceramics

Our K Lamps and Case Pendants are made from a process called Slip Casting - a renowned technique used for ceramics. They are handmade in Stoke-on-Trent, UK, an area synonymous with exceptional ceramic quality. The liquid clay, or 'slip' is mixed and carefully poured into moulds by a ceramicist. The Case Pendant is partially fired and removed from the mould, ready for glazing, before the final firing.

Shop Case Pendants